- Home

-

Our Services

- Glass Laminating Machine

- Protective Film

- Other Laminating Machines

- Aluminum Plate Laminating Machine

- Sheet Film Laminating Machine

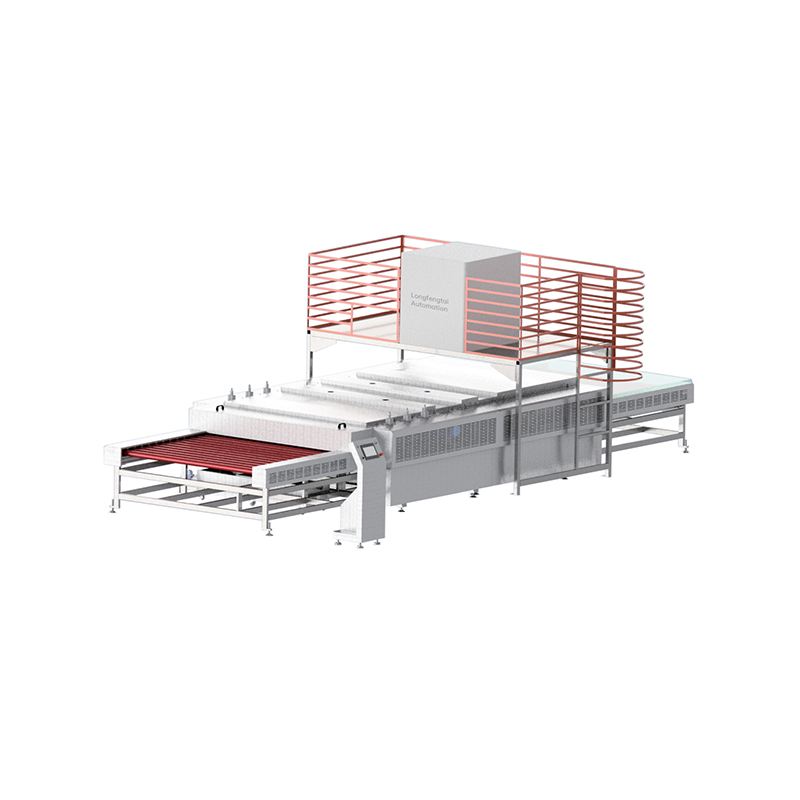

- Roller Platform Glass Laminating Machine

- Home Wood Board Laminating Machine

- Small General Purpose Laminating Machine

- Electrothermal Film Laminating Machine

- Coil Laminating Machine

- Reinforcement Steel Sheet Laminating Machine

- Pre-coating Film Laminating Machine

- Heating Laminating Machine

- Glass Laminating Machine

- Protective Film

- Other Laminating Machines

- Aluminum Plate Laminating Machine

- Sheet Film Laminating Machine

- Roller Platform Glass Laminating Machine

- Home Wood Board Laminating Machine

- Small General Purpose Laminating Machine

- Electrothermal Film Laminating Machine

- Coil Laminating Machine

- Reinforcement Steel Sheet Laminating Machine

- Pre-coating Film Laminating Machine

- Heating Laminating Machine

- Display

- Solutions

- News

- About

- Contact Us

- Partners