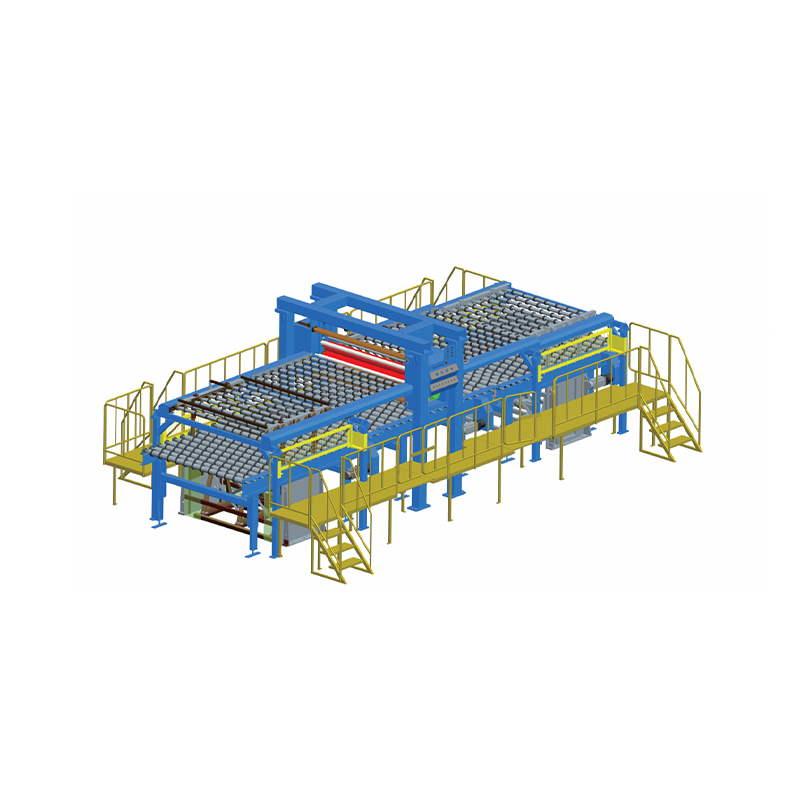

LPFM-G2000-140HPZ |

Name | Specifications | Unit |

Rated voltage | 380±10%/50 | V/Hz |

Rated power | 18.2 | KW |

Effective length of covered Cots | 2000 | mm |

Diameter of covered Cots | 140 | mm |

The hardness of the coating roller | 50-55° | HS |

Length of coated glass | 1090~1800 | mm |

The width of the coated glass | 900~1850 | mm |

Thickness of coated glass | 0.3~4 | mm |

Platform roller spacing | Horizontal 150 × Vertical 150 | mm |

Length of loading lifting table | 1820 | mm |

Width of feeding lifting table | 2000 | mm |

Length of feeding positioning platform | 2000 | mm |

Positioning to cutter distance | 1000~1600 | mm |

Adjustable product positioning interval | 5~40 | mm |

Maximum travel of cutter | 1900 | mm |

Length of discharge platform | 3480 | mm |

Length of blanking lifting table | 1820 | mm |

Width of blanking lifting table | 2000 | mm |

Adjustable range of liting speed | 10~200 | °/s |

Adjustable speed range of platform | 10~200 | °/s |

Adjustable speed of film coating | 100~700 | mm |

Speed range of discharge platform | 100~700 | mm |

Adjustable speed range of film cuting | 100~1500 | mm |

Operating pressure range | 10020×3200×2400 | mm |

Maximum film diameter | 330 | mm |

Maximum tension output distance | 5 | kg/m |

Thickness range of protective film | 0.02~0.08 | mm |

Operating pressure range | 0.4~0.6 | mpa |

Lifting height of platform | 500 | mm |

Positioning accuracy(interval) | ±1 | mm |

Conveying inclination | ±1 | mm |

Height of auxiliary arch bridge | 700 | mm |

Total weight of equipment | ≈8500 | kg |

Maximum conveying speed | 40 | m/min |

Maximum film covering capacity | 6 | pcs |