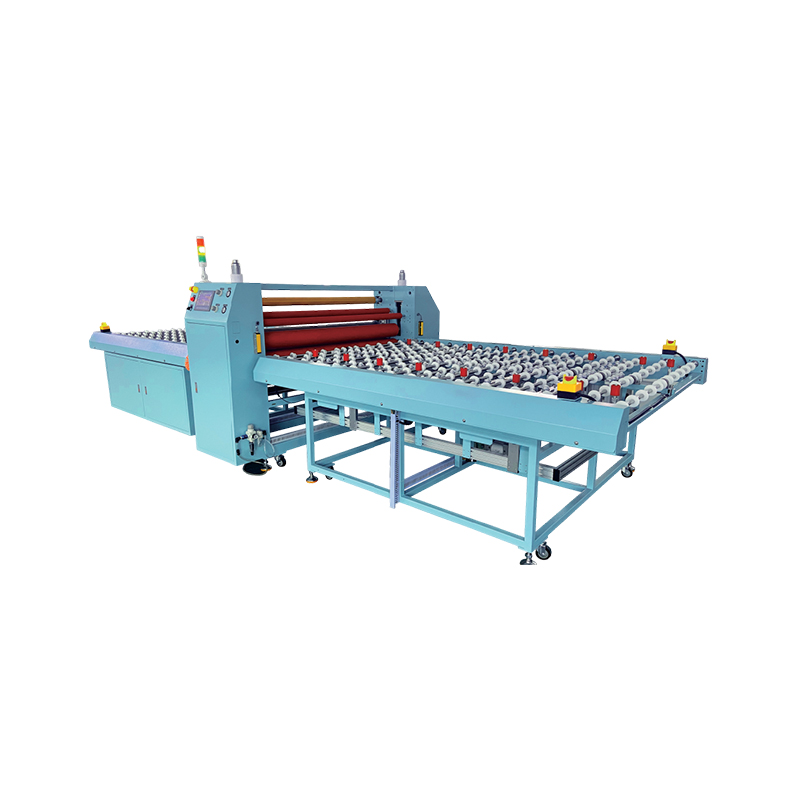

LPFM-G1650-140HP |

Name | Specifications | Unit |

Laminating roller length | 1650 | mm |

Diameter of film covered cot | 140 | mm |

Hardness of covered Cots | 55 | HS |

Number of film covered Cots | 2 | pcs |

Hardness of film cutting roller | 65~70 | HS |

Number of film cutting rollers | 2 | pcs |

Diameter of film cuting roller | 70 | mm |

Platform roller shaft spacing | 150 | mm |

Platform roller diameter | 70 | mm |

Roller spacing | 150 | mm |

Length of discharge platform | 2500 | mm |

Length of feeding platform | 2500 | mm |

Platform height(variable) | 950±50 | mm |

Length of coated products | 600~2200 | mm |

Width of coated products | 600~1500 | mm |

Film cutting plate spacing | 4~10 | mm |

Range of compound speed regulation | 1.4~9 | mm |

Thickness adjustment accuracy | 0.1 | mm |

Number of film rolls | 2 | pcs |

Inner cylinder diameter | 3 | in |

Film diameter | ≤300 | mm |

Film cutting error accuracy | ±0.5 | mm |

Cover speed range | 0~35 | m/min |

Use air pressure | 1.5~4 | kg/cm² |

Total equipment power | ≈2.8 | KW |

Power supply | 380/50 | V/Hz |

Cleanroom style requirements | 1000000 | Level |

Gas source | 4~6 | kgf/cm² |

Effective width of lamination | 1550 | mm |

Total weight of equipment | ≈900 | kg |

Dimensions | 5680×2550×1650 | mm |