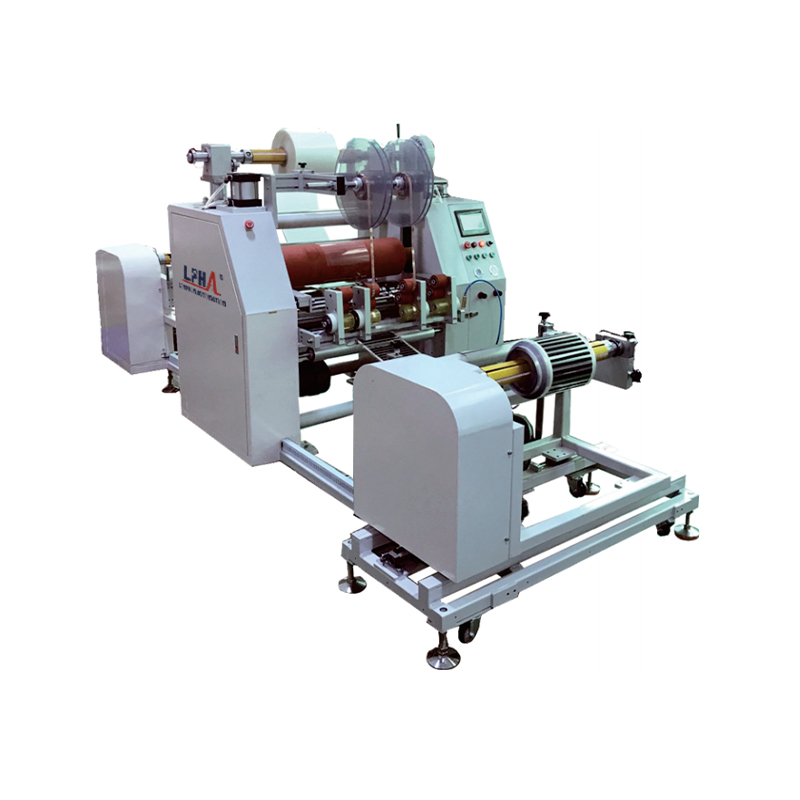

LPFM-YW700-200ECP |

Name | Specifications | Unit |

Length of steel roll under lamination | 700 | mm |

Diameter of steel roll under lamination | 200 | mm |

Length of rubber roller on lamination | 700 | mm |

Diameter of rubber roller on lamination | 200 | mm |

Cooling roll length | 700 | mm |

Cooling Roll Diameter | 150 | mm |

Heating power | 6 | KW |

Winding motor power | 0.75 | KW |

Lamination maximum pressure | 400 | kg |

Maximum film diameter | 400 | mm |

Maximum copper bar diameter | 400 | mm |

Laminate thickness range | 0~0.5 | mm |

Winding speed range | 0~12 | m/min |

Use air pressure | 0~8 | kg/cm² |

Cover speed range | 0~8 | m/min |

Maximum winding diameter | 500 | mm |

Maximum overlap width | 500 | mm |

Winding weight | 120 | kg |

Temperature range | Normal temperature ~160 | ℃ |

Laminate motor power | 1.5 | KW |

Correction motor power | 0.4 | KW |

Total weight of equipment | ≈2000 | kg |

Device input voltage | 3×380/50 | V/Hz |

Total equipment power | ≈9 | KW |

Device Dimensions | 3500×1520×1600 | mm |